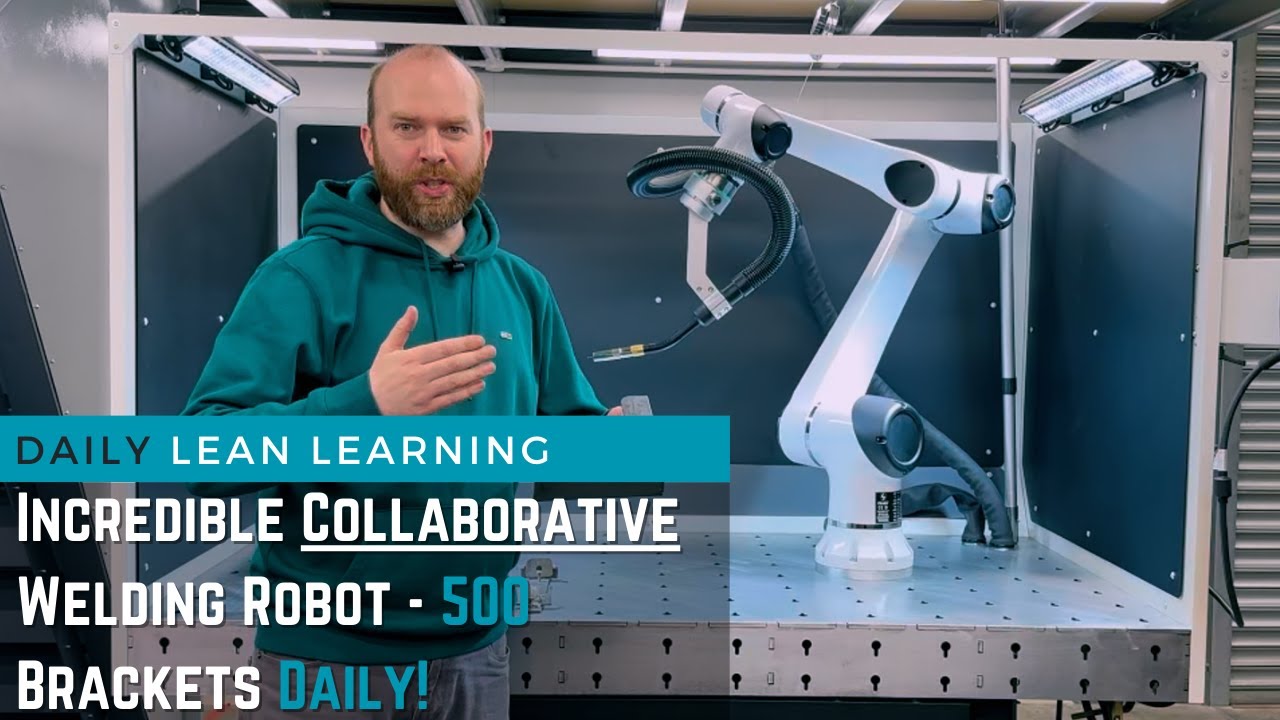

Paul’s Perspective:

This video serves as a powerful example of how embracing lean principles and valuing employee input can lead to innovation that not only meets immediate needs but also adds value to the business. It’s a vivid reminder of the potential within our teams to create transformative solutions when encouraged to think creatively.

Key Points in Video:

- Designed and built in response to high cost and long lead times of external solutions.

- Now capable of producing 500 brackets daily, significantly boosting productivity.

Strategic Actions:

- Identify organizational inefficiencies and areas for improvement.

- Encourage and leverage employee innovation and creativity.

- Apply lean thinking methodologies to design bespoke solutions.

The Bottom Line:

- Discover how a company’s journey towards waste elimination and employee innovation led to the creation of an in-house designed welding robot.

- This innovation not only solved their immediate challenges but also became a marketable product, showcasing the power of lean thinking.

Dive deeper > Source Video:

Ready to Explore More?

If you’re looking to spark innovation within your team and harness the power of lean thinking, our expertise can guide you. Together, we can explore transformative solutions tailored to your needs.