Paul’s Perspective:

Investing in advanced robotics like Atlas empowers manufacturers to address labor shortages, enhance operational efficiency, and maintain competitiveness in an increasingly automated world. Understanding emerging robotics capabilities can help leaders proactively plan for workforce transitions and innovation opportunities.

Key Points in Video:

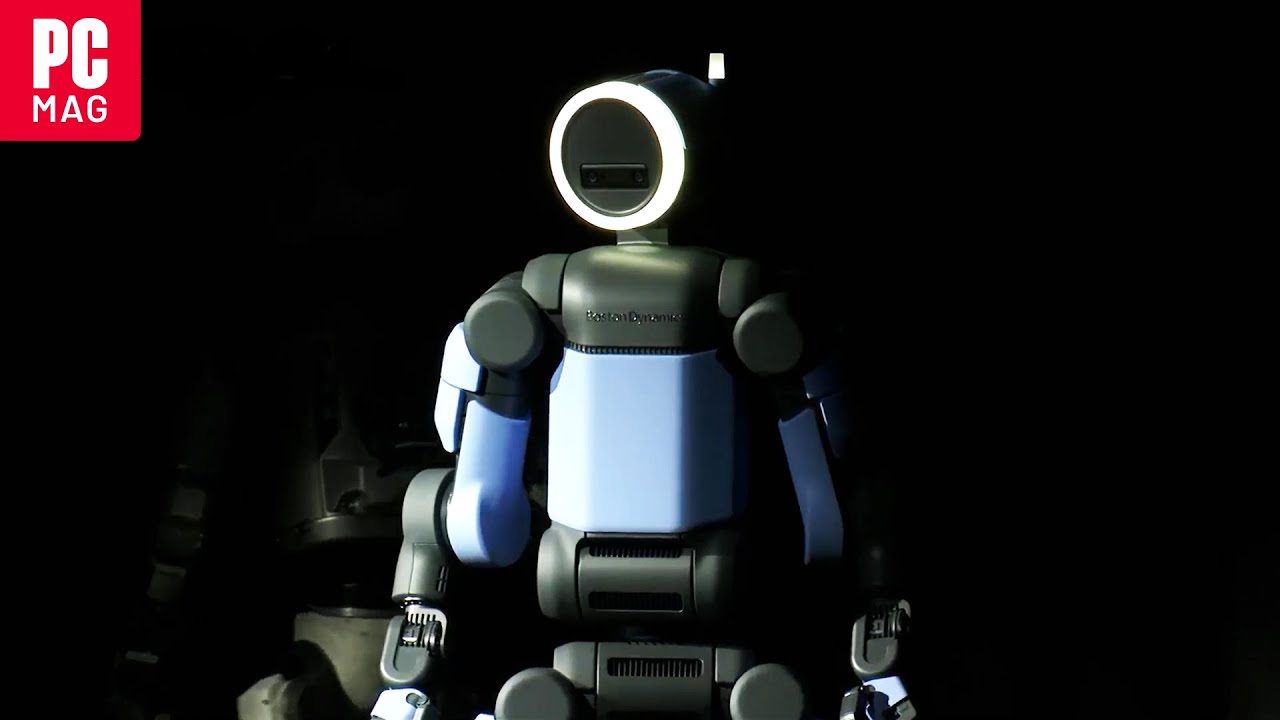

- Atlas features 56 degrees of freedom and advanced tactile hands for complex manipulation.

- The robot has 360-degree joints, robust environmental protection, and can swap batteries for non-stop operation.

- Real-world testing is underway at Hyundai’s Metaplant, with plans for global deployment in various manufacturing settings.

- Atlas is designed for autonomous movement, natural walking, and adaptable use in dynamic factory workflows.

Strategic Actions:

- Review the key features of the next-gen Atlas robot, including its all-electric design and 56 degrees of freedom.

- Understand how autonomous operation and natural walking capabilities benefit factory workflows.

- Assess the real-world testing results from Hyundai Metaplant for practical insights.

- Consider the implications of battery swapping and technical specs for scalability and uptime.

- Monitor Atlas’s global deployment strategy and adapt manufacturing plans accordingly.

The Bottom Line:

- Hyundai and Boston Dynamics have launched the next-gen all-electric Atlas robot engineered for industrial environments.

- This development marks a significant step forward in automating labor-intensive tasks in manufacturing.

Dive deeper > Source Video:

Ready to Explore More?

Our team is experienced in helping organizations assess, plan, and integrate advanced automation technologies to optimize their operations. Reach out to see how we can collaborate on identifying the right digital solutions for your business challenges.